What Does 20/2 Mean? Exploring Its Importance in Quality and Performance

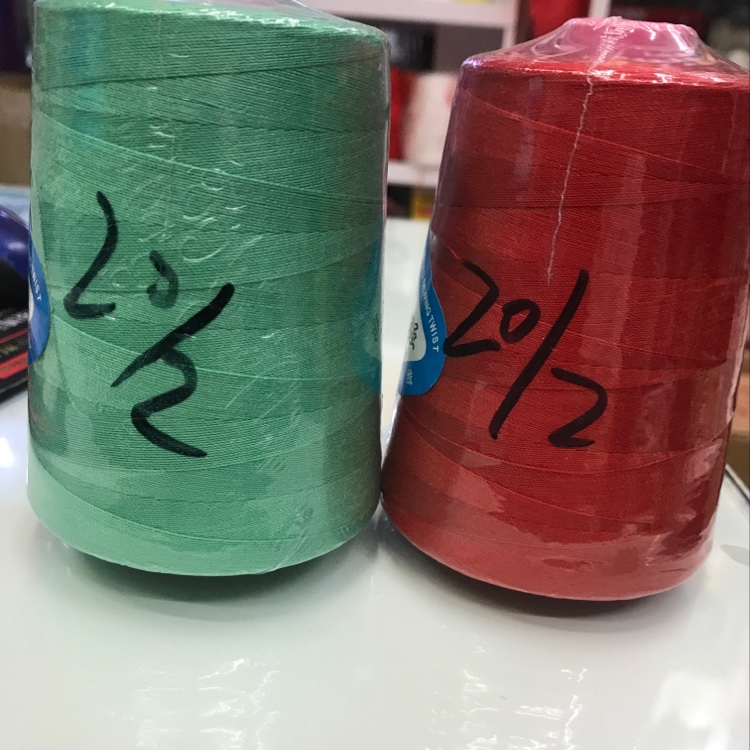

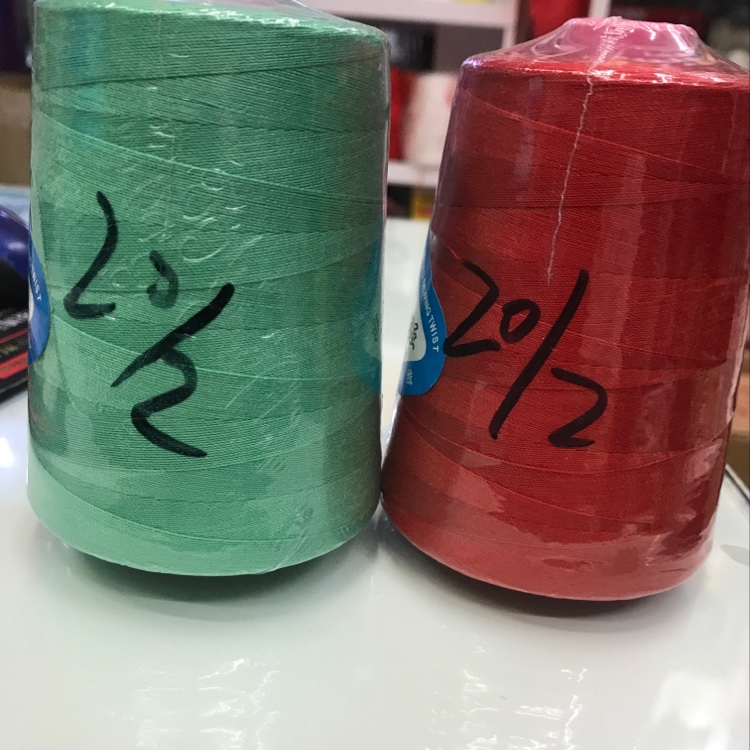

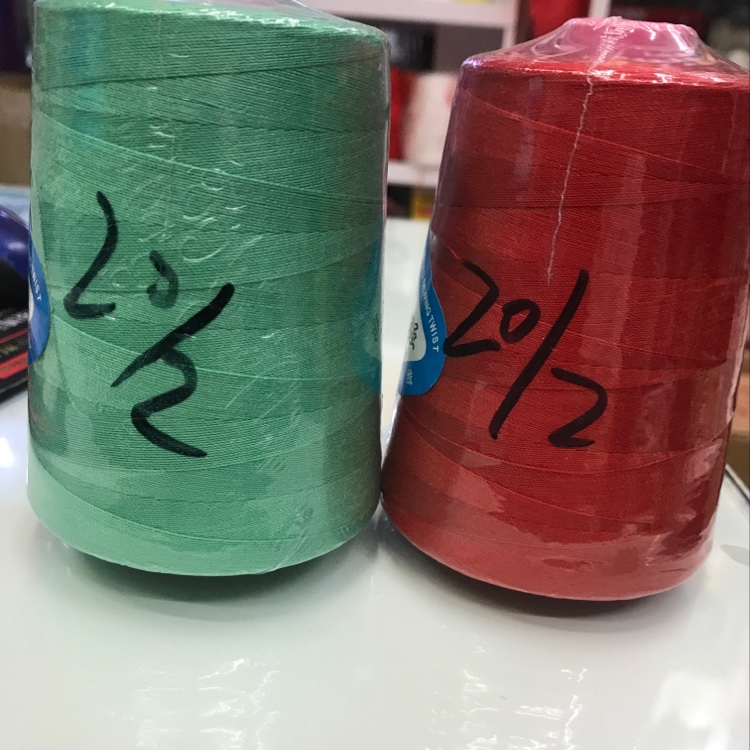

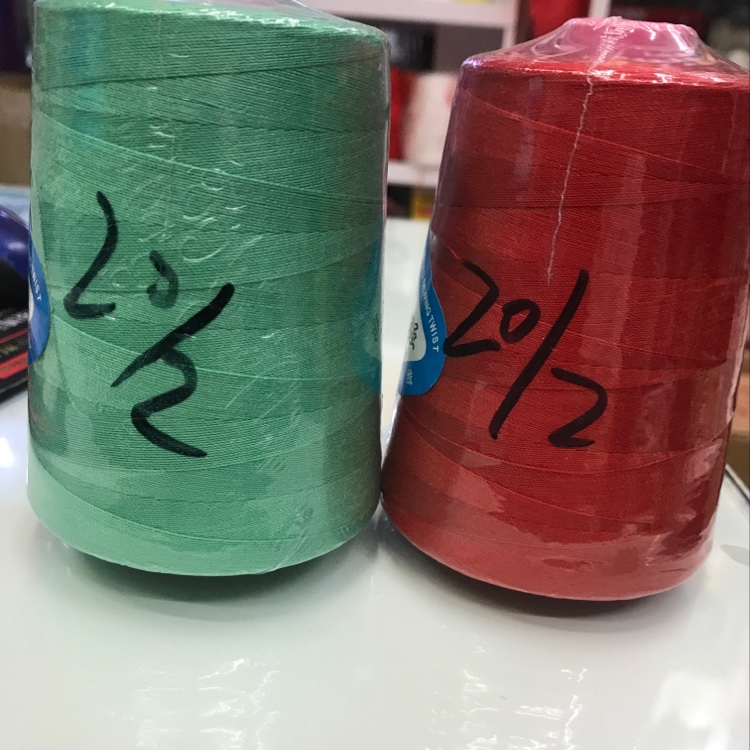

A close look at 20/2 cotton yarn — where precision meets performance.

Unraveling the Code: From Yarn to Efficiency’s Hidden Language

It’s 2 a.m., and a fashion designer sits surrounded by swatches, her fingers tracing the tiny printed tags on each fabric sample. One label stands out: 20/2. She pauses. This isn’t just a number—it’s a promise. A silent assurance that the drape will be fluid, the durability reliable, the hand-feel luxurious. In that quiet moment, she knows her entire spring collection hinges on this unassuming combination. What seems like a cryptic code is, in fact, a universal dialect of quality—a fingerprint of excellence spoken across textile mills, luxury boutiques, and high-performance supply chains.

The Dual Identity of 20/2: Numbers That Shape Reality

So what does “20/2” actually mean? Break it down: the “20” refers to the yarn count—specifically, how many 840-yard lengths of yarn can be spun from one pound of cotton. The higher the number, the finer and thinner the yarn. Think of it as musical notation: a single note (a 20s yarn) has clarity, but lacks depth. Enter the “/2”—two of those fine strands twisted together into a plied yarn. Like a chord enriching a melody, this doubling adds strength, balance, and resilience. The result? A yarn that resists pilling, holds dye more evenly, and produces fabrics with superior structure and softness. Whether in premium t-shirts or heavyweight towels, 20/2 becomes the backbone of consistency.

Industrial weaving with 20/2 yarn — precision engineering meets artisanal quality.

Beyond Textiles: How 20/2 Became a Benchmark for Performance

The logic of 20/2 transcends fabric. Across industries, professionals use its underlying principle—optimizing input for maximum output—as a mental model. In manufacturing, engineers assess materials not just by cost, but by lifespan per unit expense—essentially a “performance yield” akin to yarn count. Even logistics firms have adopted a 20/2 mindset: one company restructured its warehouse operations by measuring “packages processed per labor hour,” then doubling efficiency through process layering—much like plying threads. The outcome? A 40% reduction in delivery delays without increasing headcount. Here, 20/2 isn’t about cotton—it’s about smarter systems.

The Invisible Edge: Why Top Brands Insist on 20/2 Standards

In elite markets, 20/2 isn’t optional—it’s expected. Luxury bedding brands demand it for its perfect balance of breathability and sturdiness. Tactical gear manufacturers rely on it for field-tested reliability. And in an unexpected twist, a small Portuguese towel maker once secured a contract with a five-star resort chain simply because they refused to compromise on 20/2 combed cotton. While competitors cut costs with coarser, weaker yarns, this brand’s towels absorbed more water, lasted longer, and felt indulgent after dozens of washes. The resort’s procurement team didn’t need marketing brochures—they ran burn tests, stretch trials, and microscopic fiber analysis. The verdict? Only true 20/2 passed.

Five-star comfort starts with details—like towels crafted from authentic 20/2 cotton.

The Risk of Misreading: When 20/2 Becomes a Marketing Mirage

Not all “20/2” labels tell the truth. Some brands stamp the term for prestige while using poorly twisted yarns or inferior fibers. Consumers see the numbers but miss the craftsmanship behind them. To spot the difference, look beyond the tag: check the twist level—tight, even spirals indicate durability; examine the fiber origin—long-staple cotton like Pima or Egyptian ensures smoothness; and consider the weave compatibility—a 20/2 yarn in a dense twill performs better than in a loose knit. Without these elements, the label is just noise.

The Evolution of Excellence: Rethinking 20/2 for a New Era

As sustainability reshapes material science, even 20/2 faces reinvention. Innovators are developing bio-based yarns—such as those derived from agricultural waste—that achieve similar strength and fineness at lower counts. One breakthrough fiber, labeled “18/3,” uses triple-ply construction to surpass traditional 20/2 in moisture-wicking and tensile strength, all while reducing environmental impact. These advancements suggest that tomorrow’s quality benchmarks won’t just mimic the past—they’ll redefine it. The spirit of 20/2 lives on, not in rigid numbers, but in the relentless pursuit of better performance.

Your Choice Lies Between Two Numbers

Whether you're sourcing fabric for a new apparel line or evaluating service efficiency in your business, understanding 20/2 empowers you to see beneath the surface. It teaches us that true quality isn’t shouted—it’s woven quietly into every thread, every process, every decision. In a world of flashy claims, the most enduring standards speak softly. Because sometimes, the simplest ratio carries the most complex truth.